Our range of products

Our vector frequency converters, available in low/medium/high pressure series, offer automated service. They significantly boost production efficiency. Ideal for addressing high – rise water supply and water pressure instability issues. Moreover, they are energy – saving and eco – friendly, cutting down operational costs. A reliable choice for your business needs.

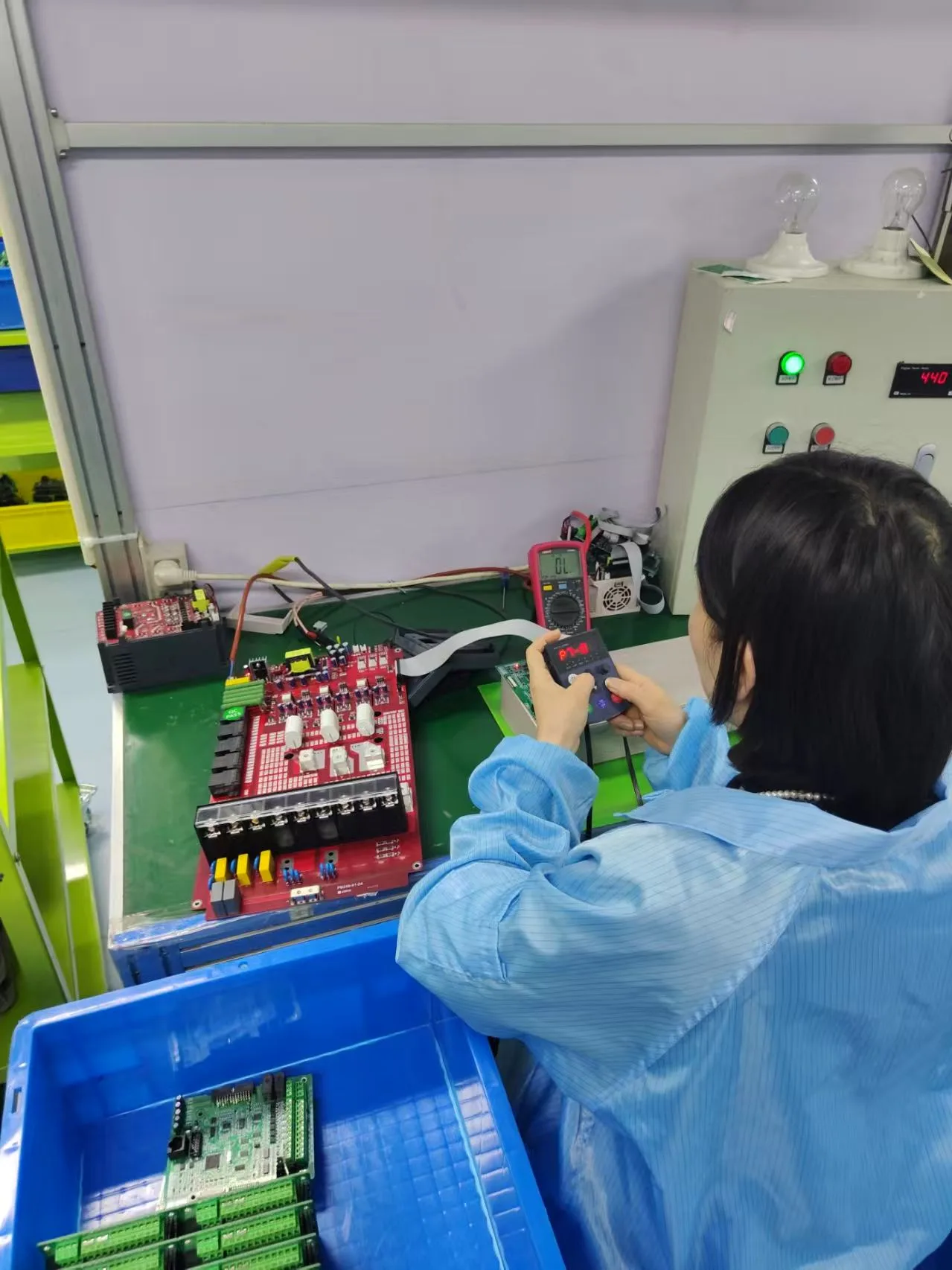

Electrical Complete Control Cabinet Supplier

We offer one – stop electrical turnkey services including design, production, programming, and commissioning.

We specialize in manufacturing various types of high and low – voltage control cabinets such as frequency converters, soft starters, PLC control cabinets, frequency conversion cabinets, soft start cabinets, constant pressure water supply control cabinets, etc.

For non – standard electrical system projects in machinery, water treatment, chemical industry, machine tools, HVAC, waste gas treatment, energy, environmental protection, and other fields, we provide complete and efficient electrical control system solutions.

Introducing our 300 series vector inverter. Leveraging smart technology, it offers outstanding performance. Ideal for diverse applications, it ensures stable and efficient operation. We’re not only a manufacturer but also provide services for project bidding and quotation. Trust us to deliver quality products that meet your business needs.

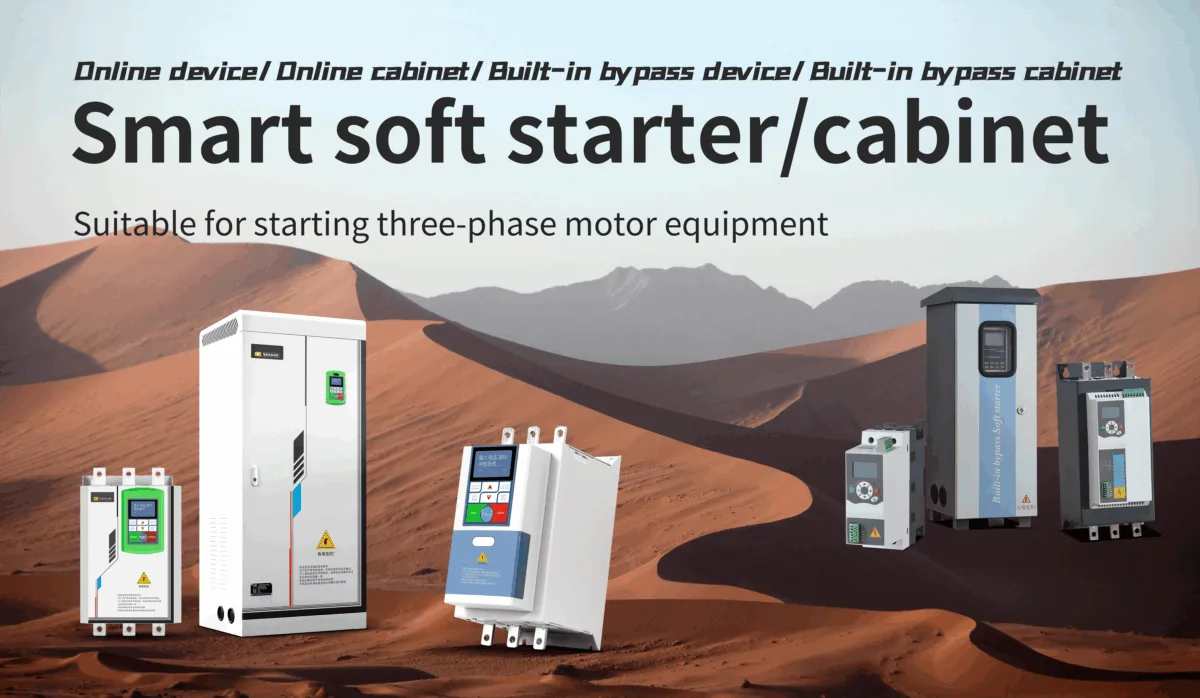

Discover our Smart Soft Starter/Cabinet, tailored for starting three – phase motor equipment. Available as online devices or cabinets, with built – in bypass options for enhanced flexibility. These solutions ensure smooth motor startups, reducing electrical stress and prolonging equipment lifespan. Ideal for various industrial applications. Partner with us for reliable, high – quality products.

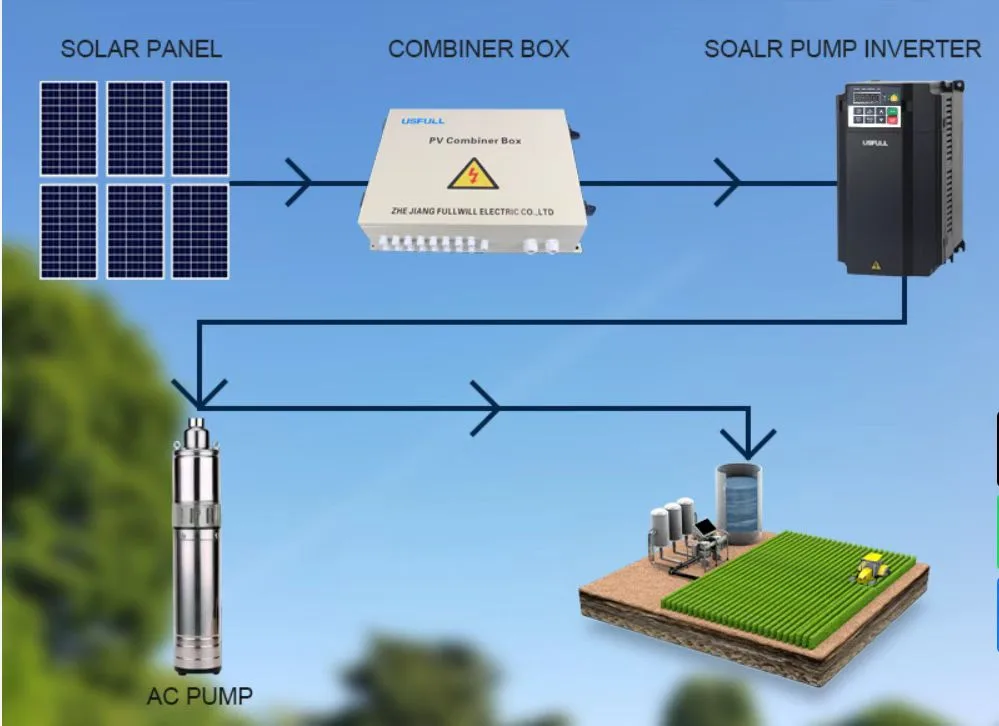

Here’s how this solar – powered system works. First, the solar panels (those square things on the left) soak up sunlight and turn it into electricity. It’s like they’re little power factories using the sun’s energy. Then, the electricity goes to the combiner box. Think of it as a traffic controller for the electricity, making sure it’s all organized.

Next, the solar pump inverter steps in. It changes the type of electricity (from DC to AC) so that the AC pump can use it. The AC pump is what does the actual work, like pumping water for crops or other needs. It’s a clean and smart way to use the sun’s power!

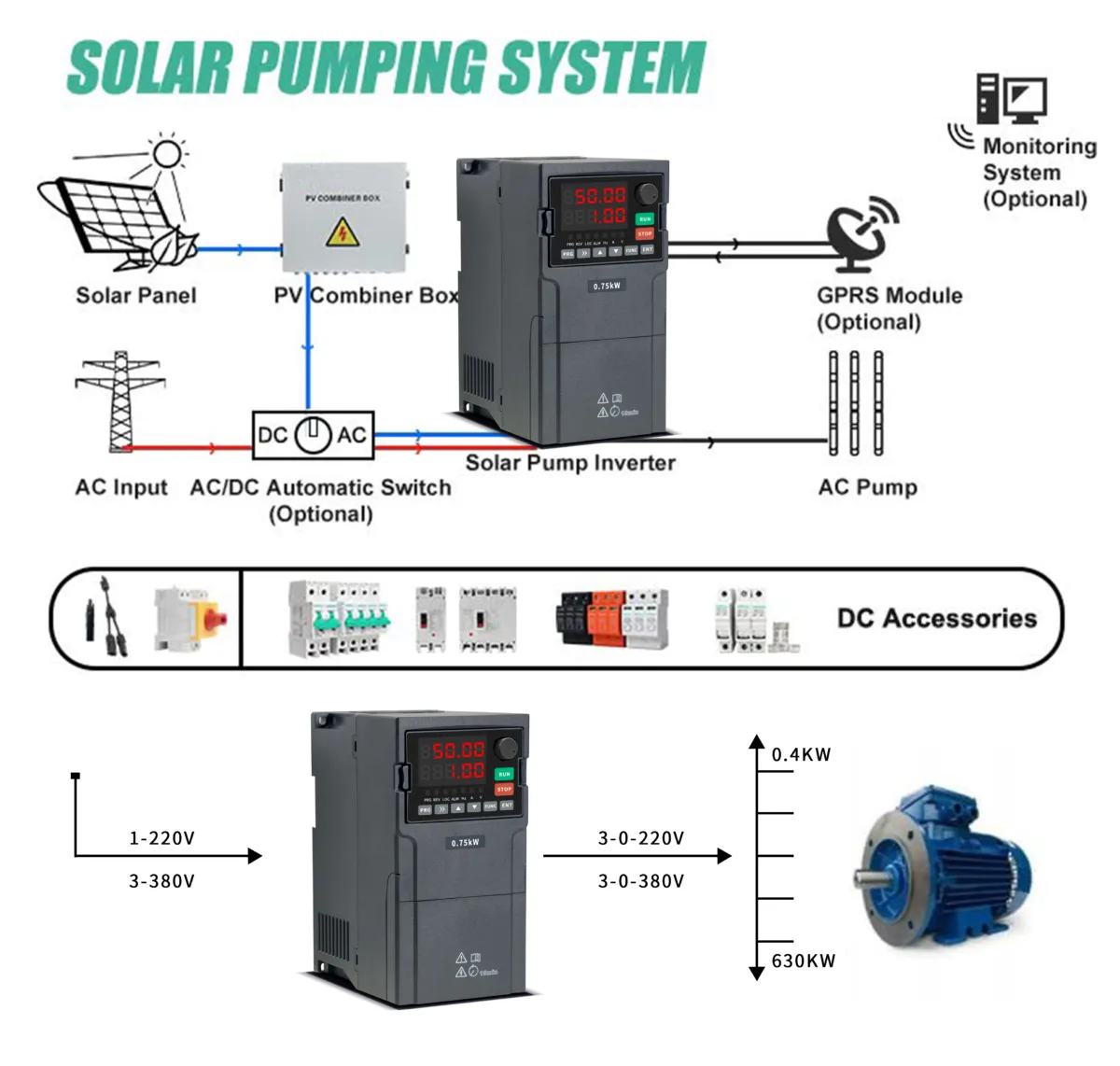

This is a solar pumping system. Solar panels catch sunlight and turn it into electricity. The PV Combiner Box then gathers this power. The Solar Pump Inverter changes the power’s form so the AC Pump can use it for pumping water.

An optional AC/DC Automatic Switch can let in power from the grid when needed. The GPRS Module (also optional) can send data to the Monitoring System, allowing you to check on the system’s work. DC Accessories help with the system’s setup. It’s a smart way to use solar energy for pumping!

Apllications

Applications in Automobile Production Automation

In automobile production automation, variable – frequency drives (VFDs) are widely used. For example, in conveyor systems, VFDs control the speed of motors, enabling smooth and adjustable material transport. In robotic arms for welding or assembly, they ensure precise speed and torque control, improving the accuracy of operations. Also, in paint – spraying equipment, VFDs help adjust the movement speed of spray guns for better paint – coating quality.

Working PrincipleVFDs first convert the incoming alternating current (AC) to direct current (DC) through a rectifier. Then, the DC power is converted back to AC with adjustable frequency and voltage by an inverter. By changing the frequency supplied to the motor, VFDs can control the motor’s speed, which in turn allows for flexible and efficient operation of various equipment in the automobile production line.

Applications and Working Principles

New Energy and Environmental Protection

In new energy like wind and solar, our electrical control cabinets manage power conversion and distribution. For example, in wind farms, they regulate the electricity generated by turbines for grid – connection. In environmental protection, such as wastewater treatment, our variable – frequency drives in control cabinets adjust pump speeds for efficient water treatment.

Our Company’s Products

Our variable – frequency drives change AC power frequency to control motor speed. Soft starters gradually increase motor voltage for smooth starts. PLC control cabinets use programmable logic to automate processes. We offer one – stop services from design to commissioning, providing tailored solutions for various industries to ensure efficient and stable electrical system operation.

Applications in Machine Tool Manufacturing

In machine tool manufacturing, variable – frequency drives (VFDs) are crucial. They’re used for spindle drive systems, enabling stepless speed regulation to meet various machining needs, thus enhancing efficiency and quality. VFDs also control the speed of cooling pumps in the cooling system based on load and temperature, saving energy. Moreover, they protect motors with soft – start and soft – stop features

Working Principle

VFDs first convert incoming AC power to DC through a rectifier. Then, an inverter changes this DC power back into AC with an adjustable frequency. By altering the output frequency, VFDs can precisely control the speed of motors in machine tools, allowing for flexible and accurate operation during manufacturing processes.

Applications in New Energy Panels

In new energy panels, such as solar panels, variable – frequency drives (VFDs) team up with inverters. They precisely control the AC output, adjusting voltage, frequency, and phase based on grid needs and power generation. This enables the maximum power point tracking (MPPT) function, ensuring the panels operate at peak efficiency and feeding electricity into the grid smoothly.

Working Principle

VFDs first change the incoming AC power to DC through a rectifier. Then, an inverter converts this DC power back into AC with an adjustable frequency. By constantly adjusting the output frequency and other parameters, VFDs optimize the performance of new energy panels, improving power generation efficiency and the stability of power supply to the grid.

Applications in Building Elevators

In building elevators, variable – frequency drives (VFDs) are crucial. They adjust the speed of elevator motors. For example, during peak hours, VFDs can make elevators run faster to handle more passengers. In low – traffic times, they slow down to save energy. VFDs also ensure smooth acceleration and deceleration, enhancing passengers’ comfort. Besides, they help with accurate leveling, reducing the risk of accidents.

Working Principle

VFDs first convert the incoming alternating current (AC) to direct current (DC) through a rectifier. Then, an inverter turns this DC power back into AC with a variable frequency. By changing the frequency sent to the elevator motor, VFDs can precisely control the motor’s speed, enabling the elevator to operate smoothly, efficiently, and safely.

The picture shows an industrial water pump unit. In such scenarios, variable – frequency drives (VFDs) play a vital role.

Applications: VFDs are used to adjust the speed of water pumps, thereby controlling the water flow rate. For example, in a water supply system, the flow rate can be flexibly adjusted according to the actual water demand to avoid energy waste. In a wastewater treatment plant, the water flow velocity can be precisely controlled according to the treatment process requirements.

Working Principle: VFDs first convert the input alternating current (AC) into direct current (DC) through a rectifier. Then, they convert the DC power back into AC power with a variable frequency and voltage through an inverter and output it to the water pump motor. By changing the frequency of the output AC power, the speed of the motor can be adjusted, enabling the control of parameters such as the flow rate and pressure of the water pump.

Applications in Factory Automation Equipment

In factory automation equipment, variable – frequency drives (VFDs) are highly useful. They control the speed of motors in various devices like conveyor belts and robotic arms. For example, in a production line, VFDs adjust the speed of conveyor motors according to the production pace, ensuring smooth material transfer. In robotic arms for assembly, they enable precise speed control, improving the accuracy and efficiency of operations.

Working Principle

VFDs first convert the incoming alternating current (AC) into direct current (DC) through a rectifier. Then, an inverter changes this DC power back into AC with an adjustable frequency. By altering the frequency of the output power, VFDs can precisely control the speed of motors in automation equipment, allowing for flexible and efficient factory operations.

Applications in Desert Areas for Photovoltaic Inverters and Water Pumps

In desert areas, photovoltaic (PV) inverters work with water pumps. PV panels convert sunlight into DC power. The PV inverter then changes this DC power into AC power suitable for the water pump. This setup enables water – pumping for desert agriculture or water – supply systems. It’s crucial for providing water in arid regions, reducing reliance on traditional power sources.

Working Principle

PV inverters first receive DC power from PV panels. They use a rectifier – inverter system. The rectifier part converts the incoming DC power to a stable DC voltage. Then, the inverter section changes this DC voltage into AC power with the appropriate frequency and voltage for the water pump, ensuring efficient water – pumping operations.

Various customized projects of ours

PLC Frequency Conversion Control Cabinet for Farmland Irrigation

Applications in Desert Areas for Photovoltaic Inverters and Water Pumps

In desert areas, photovoltaic (PV) inverters work with water pumps. PV panels convert sunlight into DC power. The PV inverter then changes this DC power into AC power suitable for the water pump. This setup enables water – pumping for desert agriculture or water – supply systems. It’s crucial for providing water in arid regions, reducing reliance on traditional power sources.

Working Principle

PV inverters first receive DC power from PV panels. They use a rectifier – inverter system. The rectifier part converts the incoming DC power to a stable DC voltage. Then, the inverter section changes this DC voltage into AC power with the appropriate frequency and voltage for the water pump, ensuring efficient water – pumping operations.

Applications in Desert Areas for Photovoltaic Inverters and Water Pumps

In desert areas, photovoltaic (PV) inverters work with water pumps. PV panels convert sunlight into DC power. The PV inverter then changes this DC power into AC power suitable for the water pump. This setup enables water – pumping for desert agriculture or water – supply systems. It’s crucial for providing water in arid regions, reducing reliance on traditional power sources.

Working Principle

PV inverters first receive DC power from PV panels. They use a rectifier – inverter system. The rectifier part converts the incoming DC power to a stable DC voltage. Then, the inverter section changes this DC voltage into AC power with the appropriate frequency and voltage for the water pump, ensuring efficient water – pumping operations.

Applications in Desert Areas for Photovoltaic Inverters and Water Pumps

In desert areas, photovoltaic (PV) inverters work with water pumps. PV panels convert sunlight into DC power. The PV inverter then changes this DC power into AC power suitable for the water pump. This setup enables water – pumping for desert agriculture or water – supply systems. It’s crucial for providing water in arid regions, reducing reliance on traditional power sources.

Working Principle

PV inverters first receive DC power from PV panels. They use a rectifier – inverter system. The rectifier part converts the incoming DC power to a stable DC voltage. Then, the inverter section changes this DC voltage into AC power with the appropriate frequency and voltage for the water pump, ensuring efficient water – pumping operations.

Applications in Desert Areas for Photovoltaic Inverters and Water Pumps

In desert areas, photovoltaic (PV) inverters work with water pumps. PV panels convert sunlight into DC power. The PV inverter then changes this DC power into AC power suitable for the water pump. This setup enables water – pumping for desert agriculture or water – supply systems. It’s crucial for providing water in arid regions, reducing reliance on traditional power sources.

Working Principle

PV inverters first receive DC power from PV panels. They use a rectifier – inverter system. The rectifier part converts the incoming DC power to a stable DC voltage. Then, the inverter section changes this DC voltage into AC power with the appropriate frequency and voltage for the water pump, ensuring efficient water – pumping operations.

INQUIRY

Leave your phone

We’ll call you in 15 min

Customize soft – starter frequency converters and cabinets with us! Simplify the process in three steps:

We turn complex Into Simple! Follow the following 3 steps to start today!

Tell us everything about your requirements. Mention the motor power, control precision, and where it’ll be used (e.g., factories, construction sites). Share any relevant drawings, pictures, and all your thoughts, whether it’s a special function or cabinet design.

Our pros will design the best plan for you. We’ll consider circuit set – up and cabinet structure. You’ll receive a detailed quote within 24 hours, so you know exactly what to expect cost – wise.

Our offices

Pls free to contact us

Our address

Yangxiang Industrial Zone, Liushi Town, Yueqing City, Zhejiang Province.China

Hero

+86 13757750205

[email protected]

Pls free to contact us

Our address

Yangxiang Industrial Zone, Liushi Town, Yueqing City, Zhejiang Province.China

Talia

+86 15968771300

[email protected]

Pls free to contact us

Our address

Yangxiang Industrial Zone, Liushi Town, Yueqing City, Zhejiang Province.China

Dana

+86 15224176197

[email protected]

Pls free to contact us

Our address

Yangxiang Industrial Zone, Liushi Town, Yueqing City, Zhejiang Province.China

Coco

+86 18958776573

[email protected]